Feature Story: A soft robotic hand driven by flexible shafts

What is a robot hand? A recent discovery by Dr. Ren Hongliang’s team may give us a better illustration.

A robotic hand is referred to as a part of the robot that can realize some functions of human hands, e.g. to pick up objects, manipulate tools. In general, robotic hands work as end effectors in robotic systems, which is the execution part of the interaction between the robot and the environment. The performance of the robotic hand largely determines that of the robotic system.

Nowadays, the application area of the robotic hand is not only limited to the industrial production line, but a large number of other areas, such as the logistics industry, academic research, and public serves, all require intelligent and reliable robotic hands.

However, the task of grasping unknown objects in unstructured and complex environments is a great challenge for robotic hands. Traditional rigid robotic hands suffer from complex and fragile structures, expensive sensors, and complicated control algorithms. As a result, most current robotic hands have the following problems: single function, limited application area, high manufacturing and maintenance cost. Flexible materials play an important role in simplifying structures, improving adaptability, and reducing the cost. Therefore, the introduction of the flexible material to the design of robotic hands can solve above the problems.

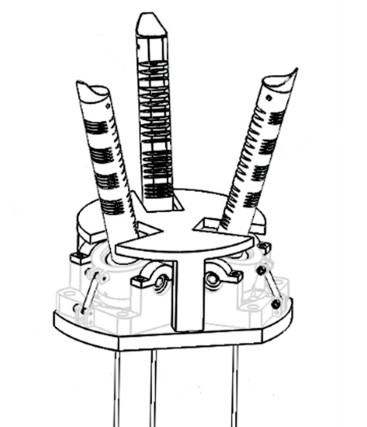

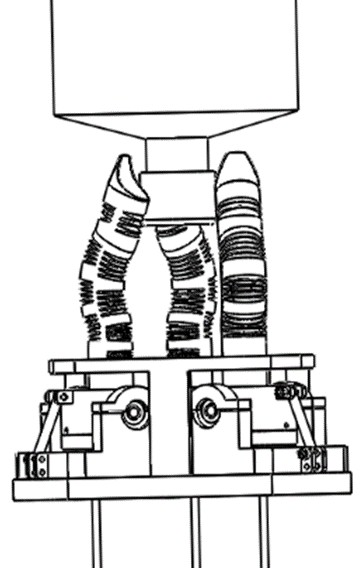

A soft robotic hand driven by flexible shafts has been developed by Dr Ren Hongliang’s Group of NUSRI.

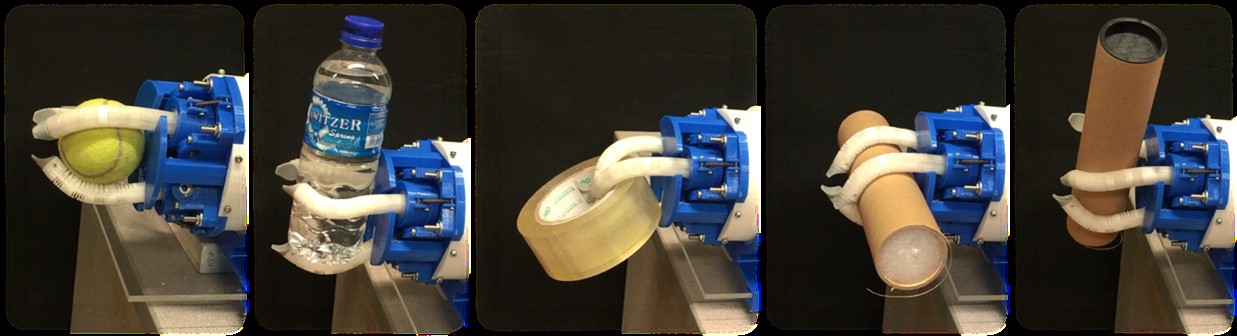

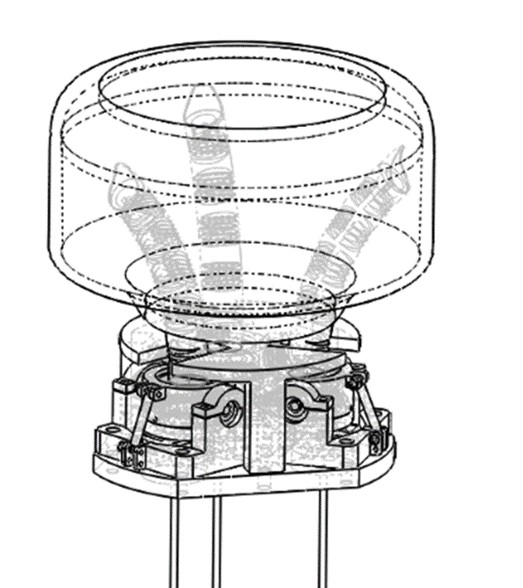

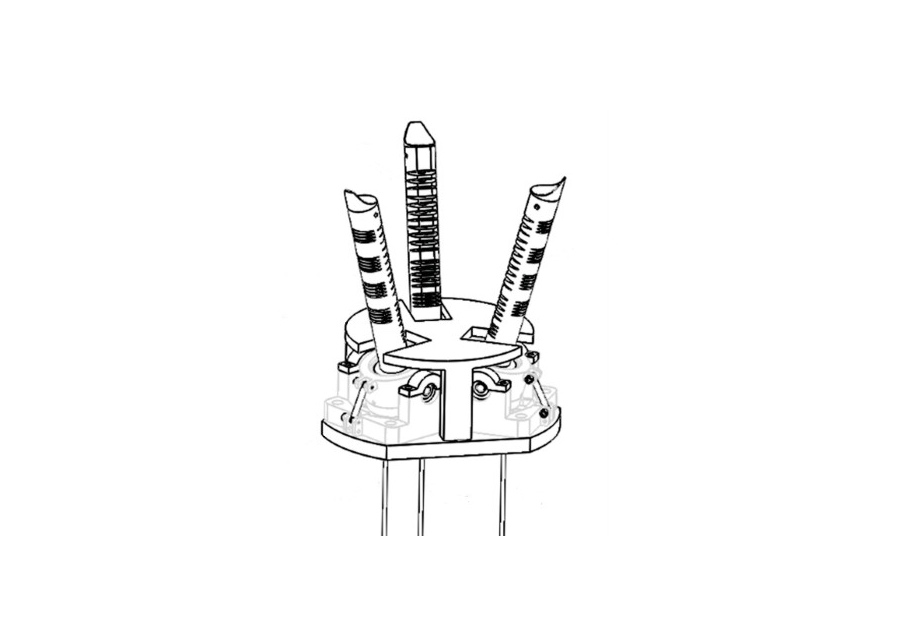

This

design has two distinct advantages. Firstly, the robotic

hand consists of three soft fingers, which are 3D

printed with a novel flexible material named NinjaFlex. These fingers feature

better flexibility, reduced manufacturing time, and lower cost. Secondly, when compared with the

cable-driven mechanism, the flexible shaft can not only to transmit pulling force to drive the finger to generate bending

motion and grasp objects, but also transmit torque to actuate the finger to

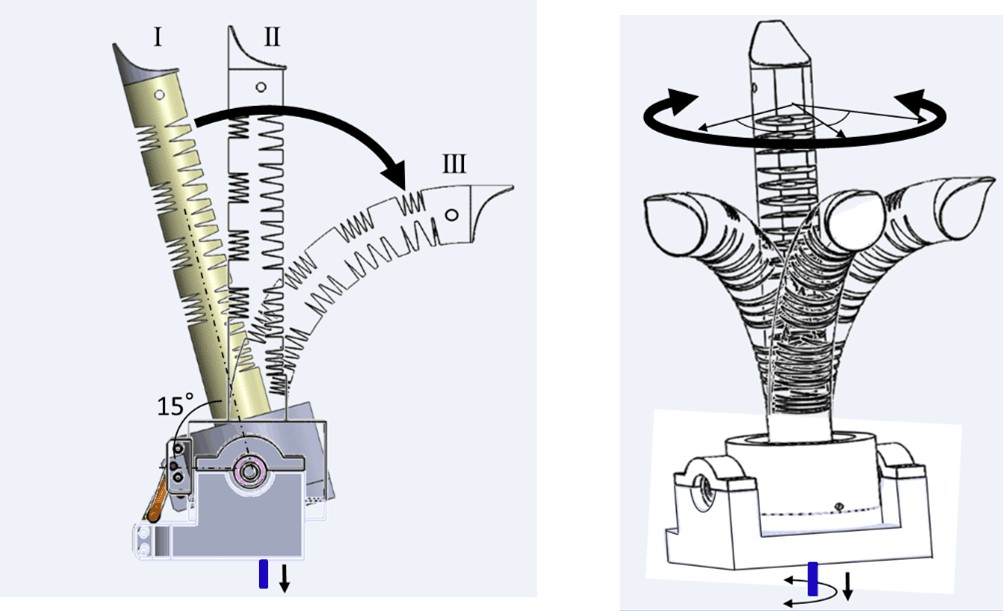

rotate around the finger base. As illustrated in Fig2, the designed robotic

hand is capable of robustly grasping objects with different outlines and

different weights without additional sensors and complicated control

algorithms. Moreover, this robotic hand can grasp the same object in different

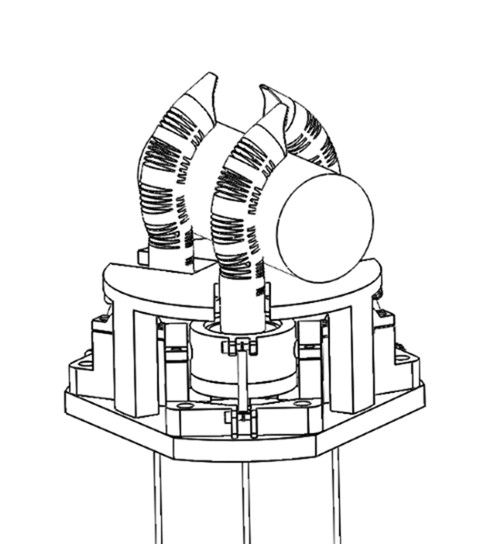

ways by rotating fingers when the base of the hand is fixed. This significantly improves a robot hand’s dexterity. In

addition to its excellent grasping ability, the

developed robotic hand has the ability to complete the twist operation, e.g.

loosen a cap from a bottle (see Fig. 3), without any additional DOF. Therefore,

this robotic hand can be applied in many different

scenarios, such as turn knobs in some machines, valves in dangerous environments.

The introduction of flexible materials and flexible shafts into the design of the robotic hand can effectively simplify the structure, reduce costs, increase the scope of application, improve the stability, and enhance the functionality. Lastly, it is of great importance for the popularization of robotic hands.