Feature Story: Cable-driven modular robotic hands with reconfigurable joints

For robotic hands, the most traditional actuation method is to place motors at every joint, which achieves good control performance. However, robotic hands adopting this actuation method are clumsy and bulky, which severely limits their scopes of application. The cable-driven mechanism allows the actuation part to be separated from the main body of the robot contributing, which is effective in reducing the size of the robot. However, most robotic hands employing this mechanism have fixed configurations and are not applicable to objects with great variation in shape. To solve the abovementioned problem, this design incorporates the design concepts of modularization and reconfigurable joints for the first time. Potential implications such as the connection between each module, reliability of connections, have been solved; and two prototypes have been developed.

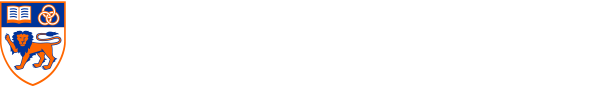

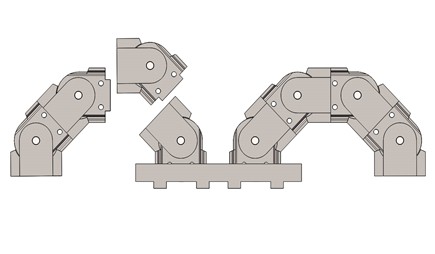

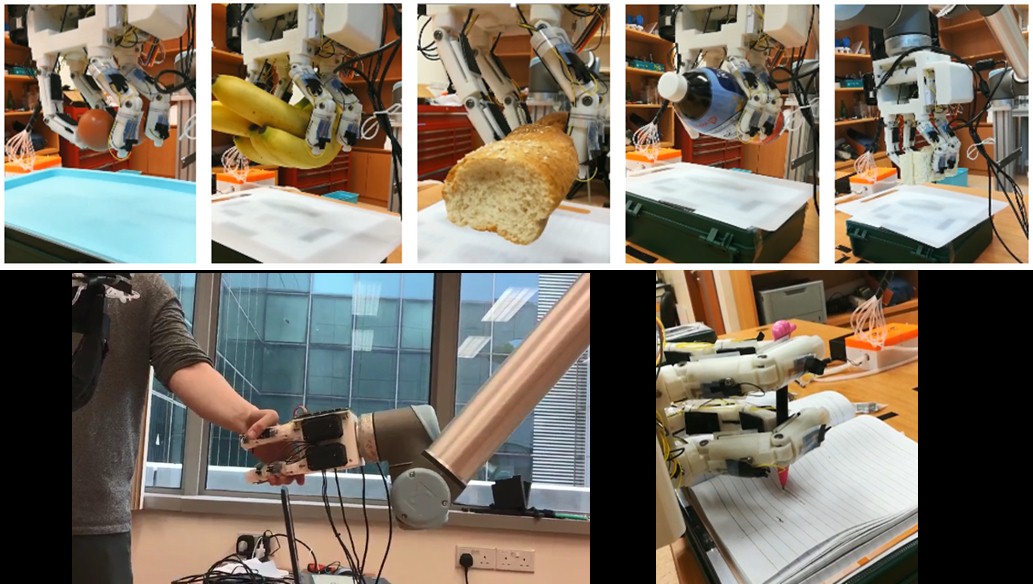

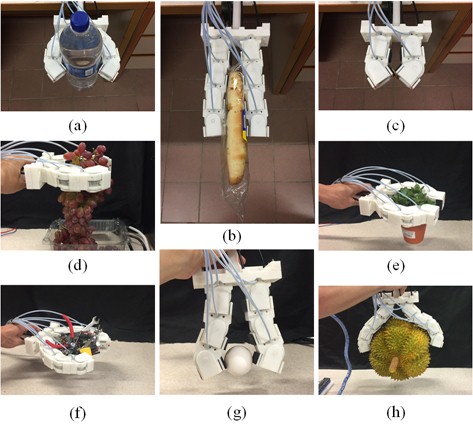

For the first prototype, each finger is comprised of identical modules. Every module can be easily replaced by a new one contributing to reduced maintenance cost. In addition, the number of modules each finger can give can be arbitrarily changed according to different tasks. Moreover, all joints can be actively locked. This allows the robotic hand to form different configurations to complete various tasks. When an intelligent control algorithm is proposed, the finger joints can be automatically locked when corresponding modules contact the object. When all finger joints are locked, the robotic hand is able to lift the object without any additional actuation force. As such, reconfigurable joints not only diversify the configuration of the robotic hand and enhance the grasping ability, but also effectively reduce the maintenance costs by means of protecting actuators and increasing their service life.

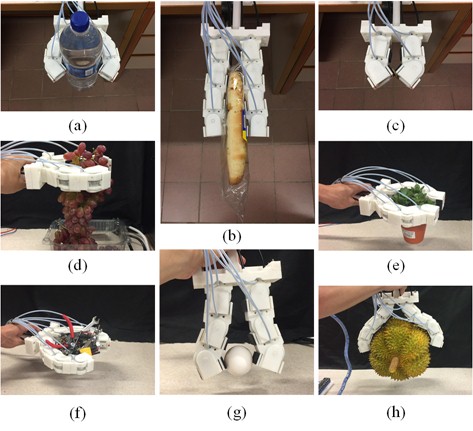

The second prototype also employs the same design concept of modularization. The connection mode between modules of the finger is also utilized to connect fingers to the base of the robotic hand. Therefore, the workspace and stiffness can be easily reconfigured by changing the number of modules each finger has or adjusting the location of fingers in the base of the robotic hand. This plays an important role in broadening the scope of application and enhancing its grasping ability. This allows the robot hand to demonstrate excellent performance in human-robot interaction and when operating with certain tools.

By virtue of the modular design concept and reconfigurable joints, the workspace, the configuration and the stiffness of the two prototypes can be adjusted according to different tasks. This would significantly increase the flexibility and compliance of these two robotic hands. Moreover, the intelligent sensing ability and adaptability contribute to the enhanced grasping ability and broadened scope of application. Meanwhile, structures of these robotic hands are simpler and can be manufactured using 3D printing technology, which contributes to a shortened production cycle, reduced manufacturing cost, and improved versatility.